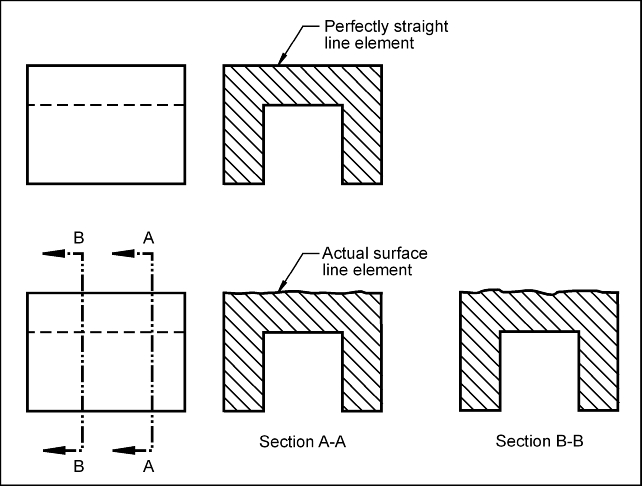

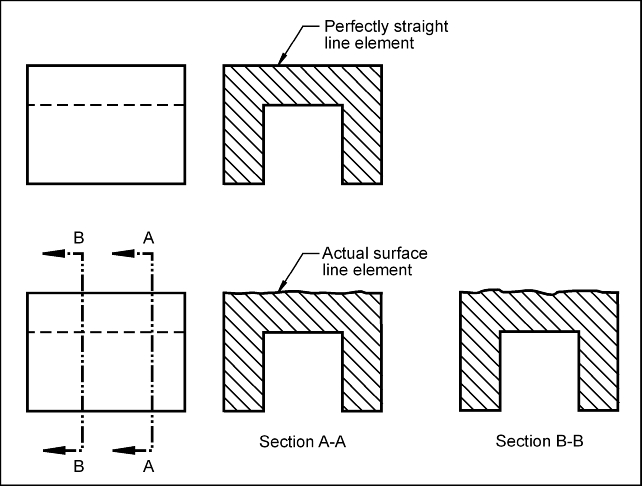

Consider the two surfaces line elements shown. Which line element is straight? In reality, no part surface is perfectly straight. How would we know if the surface on the bottom is straight enough?

The straightness tolerance may be used to control the straightness of a planar surface, a cylindrical surface, a center plane or a centerline. The straightness control as applied to a surface or a center plane is very similar. Differences arise with the application of the feature control frame and inspection. When differences occur they will be explicitly explained.

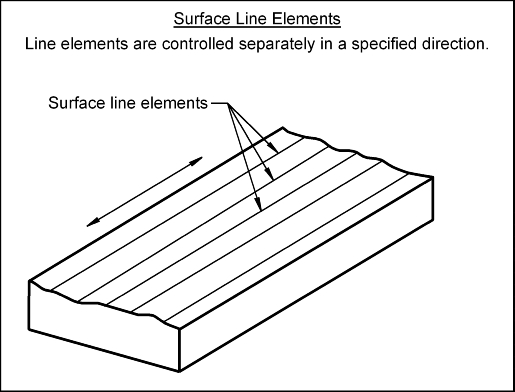

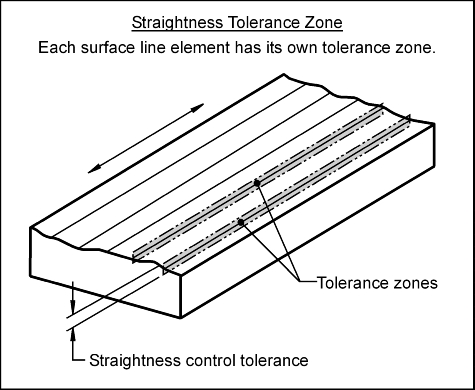

When controlling a surface, the straightness control (u) defines how much each surface line element in a specified direction may deviate from a perfectly straight line.

Straightness Control: Perfect straightness occurs when all points of an element lie on the same line. Straightness is a form control. The straightness control (u) defines how much each surface line element in a particular direction on a real part may vary from an ideal straight line.

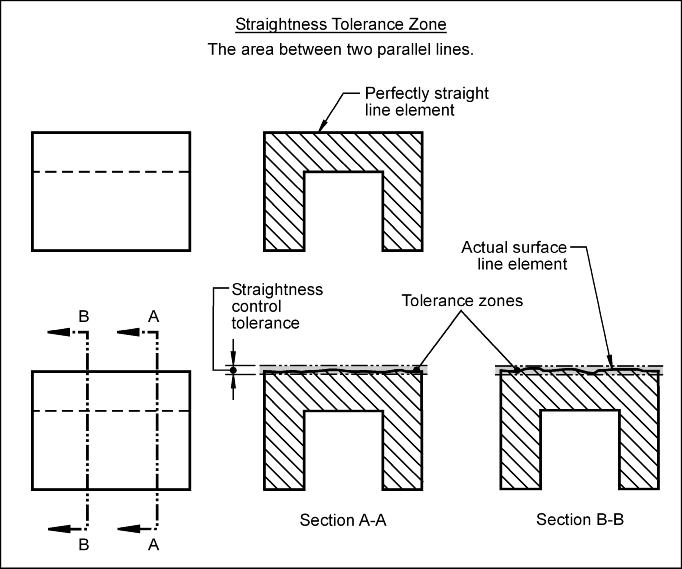

Tolerance Zone: The straightness tolerance zone is the area between two parallel lines. The distance between the parallel lines is the value of the straightness control tolerance. Each line element of the surface in the direction specified must, independently, lie within the area defined by the tolerance zone.

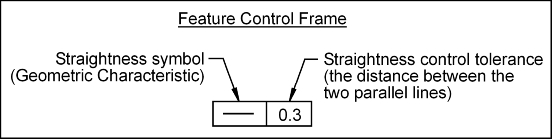

Feature Control Frame: To control the straightness of a surface, a feature control frame (FCF) is used to apply the tolerance to the desired surface.

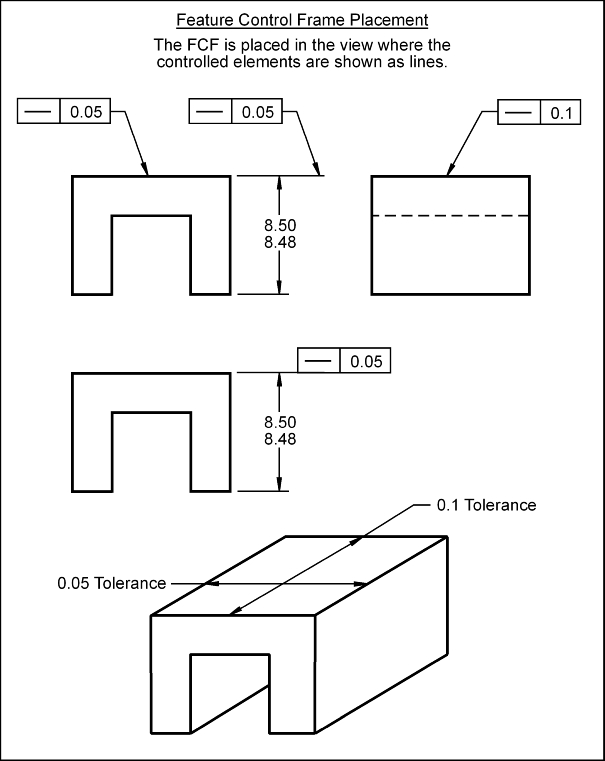

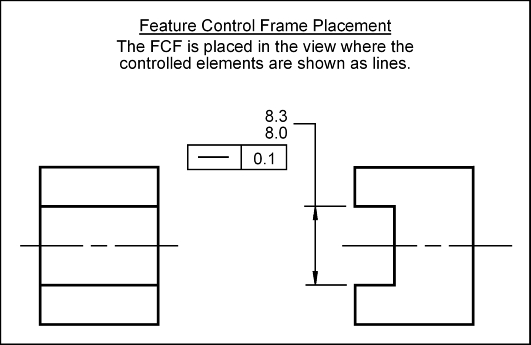

Feature Control Frame Attachment – Planar Surface: To apply a straightness control to a surface, the FCF is placed in the view where the controlled surface elements appear as lines. The FCF may point to the surface or the extension line that extends from the surface. The FCF’s shown below apply a straightness tolerance to the entire surface is opposing directions. The surface elements must, independently, lie between two parallel lines that are 0.05 mm apart in one direction and 0.1 mm in the other.

Feature Control Frame Attachment – Center Plane: To apply the straightness control to a center plane, the FCF is associated to the size dimension. Whenever a FCF is attached to a FOS dimension, it applies to the axis or centerplane of the feature. The FCF shown below applies a straightness tolerance to the part’s center plane. The center plane line elements must, independently, lie between two parallel lines that are 0.1 mm apart.

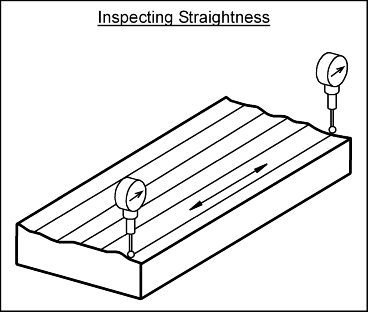

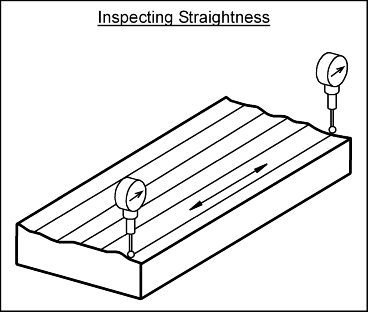

The straightness control may be inspected as follows:

Before the straightness of center plane may be assessed, it has to be located. The location of the center plane may be determined and inspected as follows: